FROM MOLD DESIGN - MANUFACTURING TO SHEET METAL PROCESSING, LEAVE IT TO US

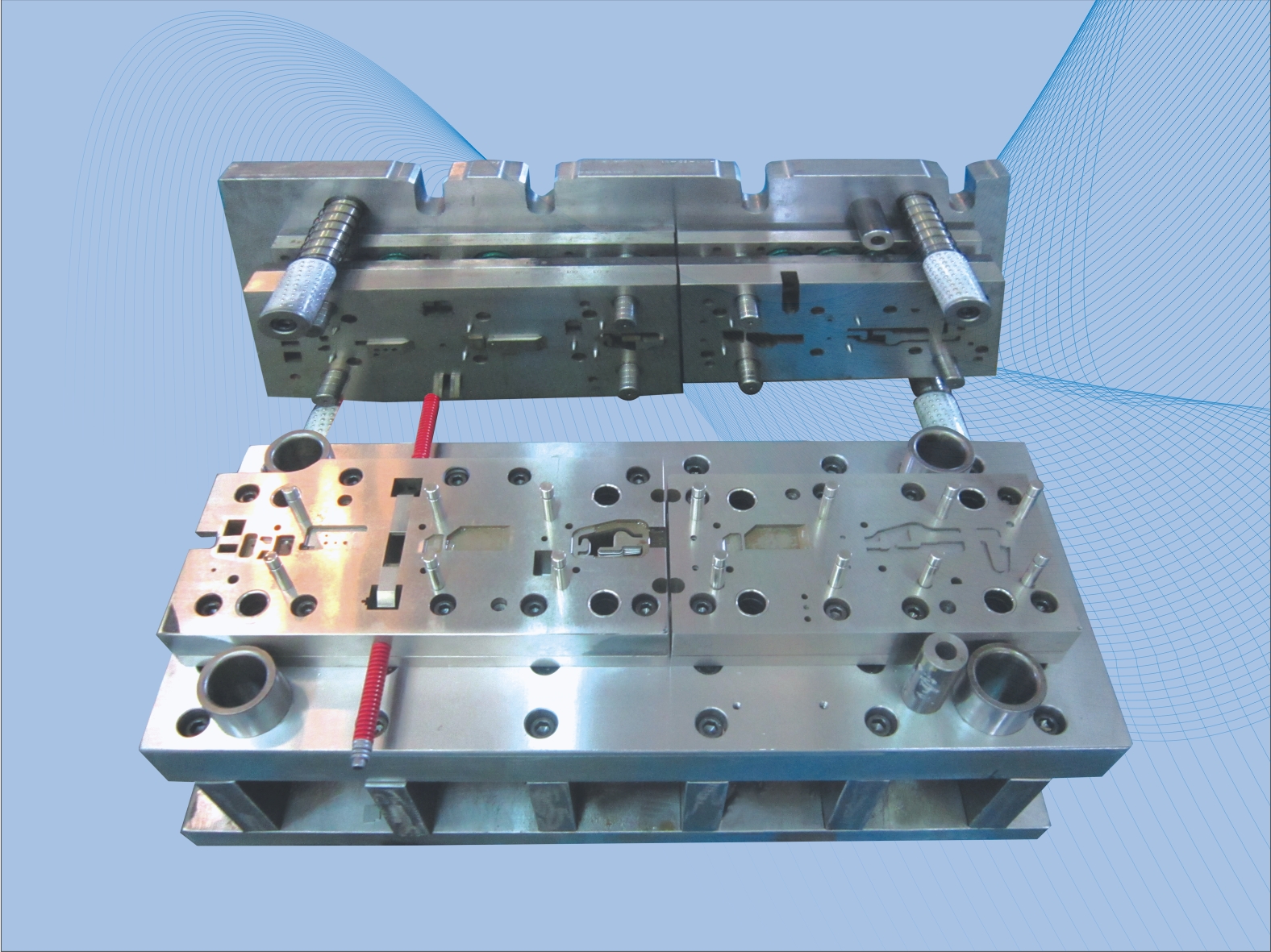

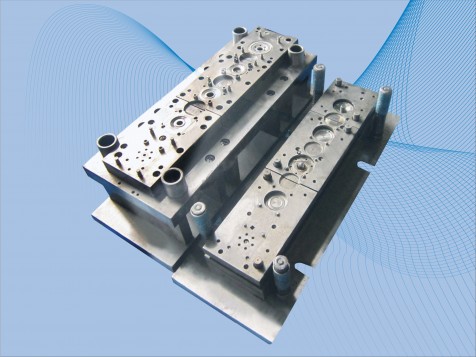

【Design – Manufacturing of stamping dies】

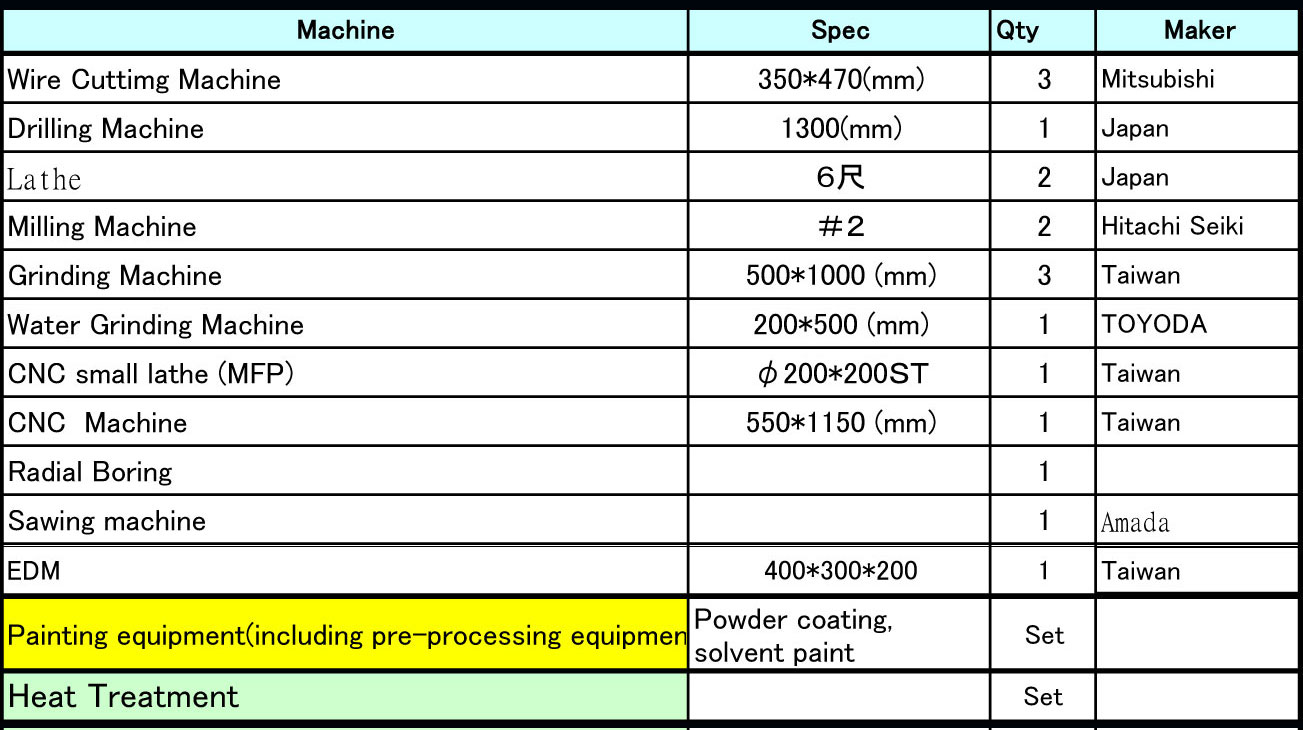

Since our establishment, we have always strived to manufacture and apply mold making techniques based on methods accumulated over many years. After using the CAD system designed according to customer requirements, with equipment such as milling machines – lathes – grinders – machining centers, wire cutting machines – welding machines…, we always try to maintain quality stability based on high performance in work. From molds to precision stamping dies, depending on budget and needs, we prepare equipment to meet a variety of design – manufacturing models. So, anyone who needs help with the mold please contact us.

Zinc plating, Nickel – Chromium plating is expected to go into operation in September 2015.

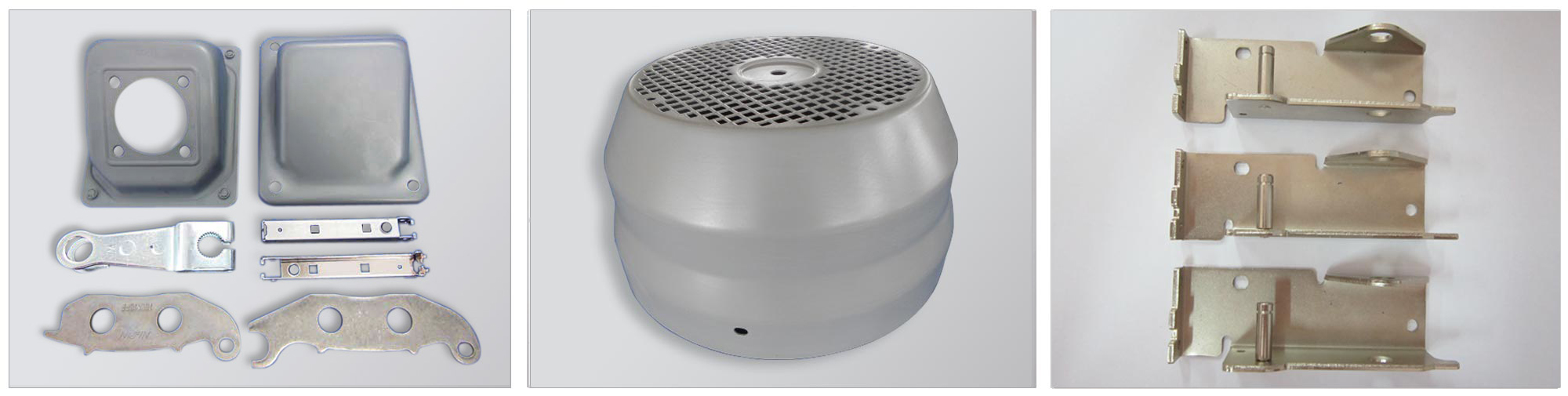

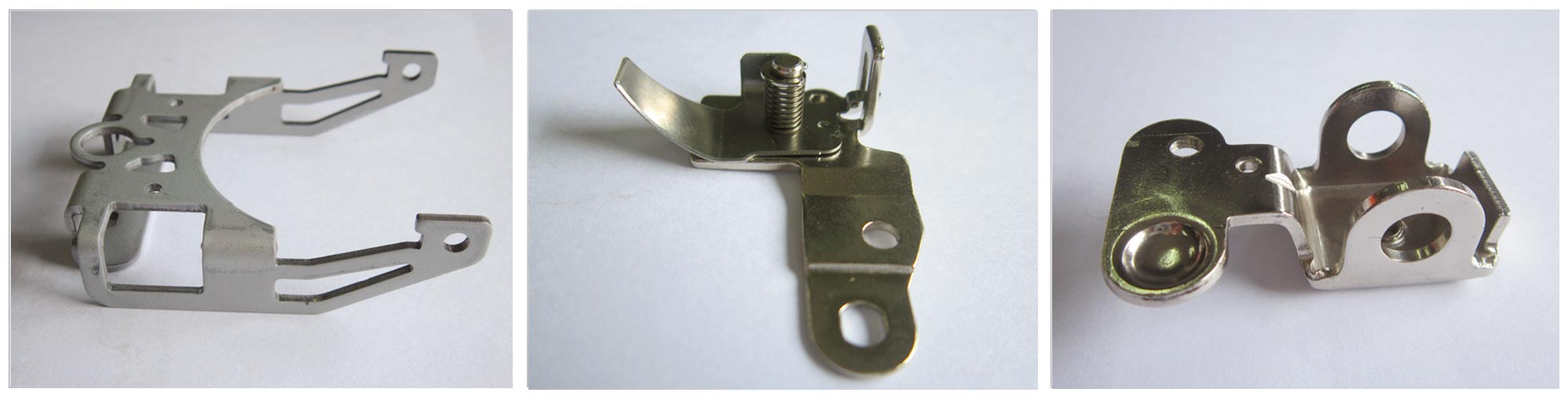

【Stamping processing — Needle plate type】

From continuous die From sheet metal processing, mechanical processing, tools and equipment to design, testing, mass production, cost reduction proposals…, are all done at Okura’s factory. At Okura, sheet metal, metal molds, corner molds, and machine processing are carried out synchronously, so production is carried out according to the most suitable processing method, corresponding to the quantity of products.

【Material】: SUS、AL、SK、SECC、SGCC、SPCC、SPCF、SAPH440、SS400、 And other materials

【Thickness】: t0.10 ~

Part name:Kanet Beer Tank

Material: SUS 304

Fix the mold, put the material in the middle and then form a block, For example, processing into containers such as aluminum cans…. Processing applies high technology and meticulousness to every detail to avoid creating wrinkles, dents, butt,…